Additives for Abrasives

Our abrasive additives are ideal for all forms of grinding and cutting, such as precision grinding, rough-, cold and hot-grinding.

Abrasives

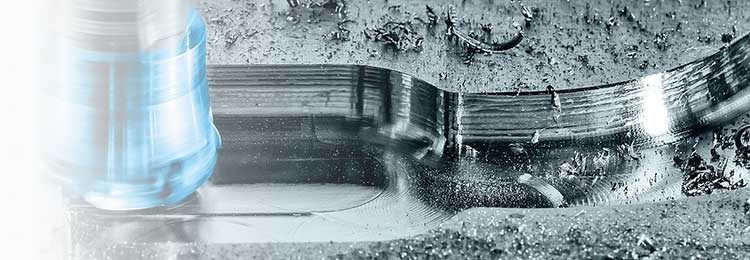

Metal sulfides are crucial when it comes to improving the grinding pattern and the severing process. They create an increased cross-section, improve temperature dissipation during the cutting or severing operation, reduce oxidation of the cutting area and extend tool life.

Taking care of the final finish

Grinding is used for the fine finishing and finishing operations of work pieces to give them their final shape and provide high surface quality. Tribotecc offers its customers high-quality functional additives ideal for grinding and cut-off wheels, dressing and drilling tools.

Perfect for grinding and cutting

The active fillers manufactured by Tribotecc are used mainly in resin-bonded grinding and cut-off wheels, shortening processing time while increasing the quality of the grinding pattern. The advantages for the users are multiple; an extended tool life (g-ratio) even at high cutting performance, no scuffing, a reduced friction coefficient, a reduced or even no oxidation of treated materials and no discoloration of treated materials such as steel. Our metal sulfides and complex chlorides are suitable as abrasive additives for wheels of any shape and diameter

Product

Range

OTHER PRODUCTS

- Synergistic solid lubricant systems based on synthetic metal sulfides (SLS-, WEP-series)

- Complex chlorides based on manganese

- Tin metal powder

- Antimony metal powder

BEST PERFORMERS

- Tribotecc - Pyrox®

- Tribotecc - MKC-S

- Tribotecc - KEP 2

- Tribotecc - GWZ 100P

- Tribotecc - CPX 50G

Tribotecc Abrasives

- Improve tool life (g-factor) under high cutting force

- No scuffing

- Reduce friction coefficient

- Ensure cool cut

- Reduce oxidation of the treated material

- No discoloration of steel