Functional additives for

powder Metallurgy

Our synthetic sulfides ensure that sintered parts are readily machinable and withstand maximum stress.

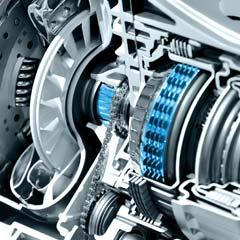

Dealing with maximum stress

The use of synergistic synthetic metal sulfide systems based on manganese, molybdenum, bismuth and tungsten sulfides promotes better machinability of sintered parts. This results in an increased tool life. For the first time, Tribotecc products can be used to enhance the tribological properties and thus the lifetime of sintered components.

Sintered parts - high durability

In powder metallurgy, metal powders and additives are mechanically compressed and subsequently sintered into highly stressed components. The functional additives by Tribotecc support the production of high-performance parts particularly used in vehicle engines.

High-performance due to metal sulfides

Tribotecc supplies a range of metal sulfides mainly based on manganese, molybdenum, bismuth and tungsten sulfides for the manufacturing of sintered parts. Even low concentrations of these functional additives lead to a better machinability and improve the tribological properties of the sintered powder matrix. As a consequence, high numbers of sintered parts can be produced in a cost-efficient way. They have complex geometries, withstand extreme stresses and are therefore eminently suitable for the use in automotive industry and other industries.

Product

Range

OTHER PRODUCTS

- Synergistic solid lubricant systems based on synthetic metal sulfides (SLS-, WEP-series)

- Complex chlorides based on manganese

- Tin metal powder

- Antimony metal powder

BEST PERFORMERS

- Tribotecc - MNS 2

- Tribotecc - MBI 15

- Tribotecc - MNC 21

- Tribotecc - WS-series

- Tribotecc - MNS LOX

Tribotecc Powder Metallurgy

- Improve machinability

- Enhance microstructure

- Superior tribological effects

- Reduce friction coefficient

- Reduce wear